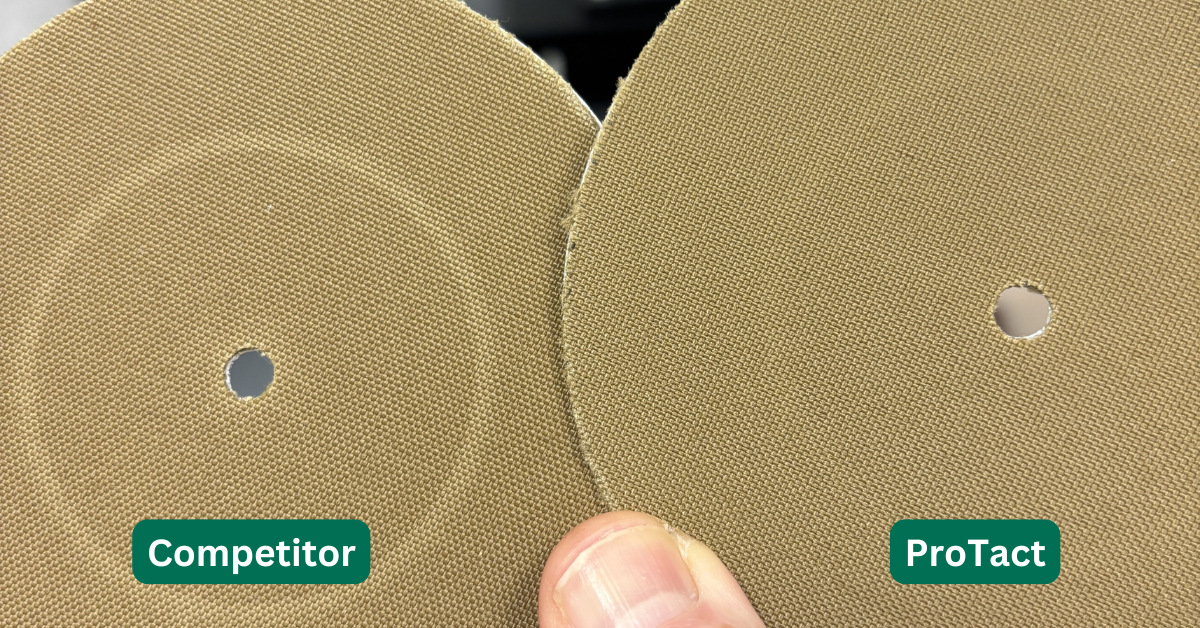

The tactical fabric industry faces a critical challenge as EPA mandates drive the transition to PFAS-free DWR finishes. Many fabrics with PFAS-free DWR finishes suffer visible scuffing and surface damage from basic handling - an unacceptable compromise for manufacturers who strive to deliver premium quality products to discerning customers.

"Any minute manipulation of fabric via folding, turning a product inside out, abrasion etc would cause the fabric surface to become marred," explains Jesus Rodriguez, President of Coyote Tactical Solutions. "The fabric structure would appear to take on a white spider web like appearance."

That’s where ProTact by Haartz® can help. ProTact is a line of advanced technical laminates specifically developed for military, law enforcement, SWAT teams, and other tactical applications. It’s available in multiple colors and patterns and is now available in PFAS-free DWR finish options across all colors and patterns.

"We recently conducted side-by-side comparisons after a standardized Taber® Scuff test," said Samit Sadavarte, director of business development for new markets for Haartz. “The test is very rigorous and is much rougher on the fabric than the typical fabric manipulation needed for product production.”

ProTact demonstrated minimal surface marring even after aggressive scuff testing – a stark contrast to competitor materials. The difference is clear in side-by-side comparisons. Where competitors show obvious wear, ProTact maintains a much higher quality appearance.

The impact on production efficiency is significant too.

"We've tried products from other companies, but ProTact has become our new laminate choice," said Jonathan Jasinski B. from Bear Tactical Gear. "It's incredibly soft and yields perfect cutting and engraving results. Other, stiffer laminates take days to straighten out. ProTact is ready straight from the roll, speeding up our entire production."

For tactical gear manufacturers, this innovation means they can meet environmental requirements without compromising the durability their customers demand. The proof is in the performance - ProTact maintains exceptional mark-off resistance during bending, folding, and sewing processes while meeting PFAS-free requirements.

In an industry where excellence isn't optional, ProTact is setting a new standard for PFAS-free tactical laser cut laminate fabrics.