The 2024 NASTT No-Dig Show is in the books. During the event, we had the opportunity to engage with a wide range of CIPP professionals and installers. Through our conversations, we've identified three trends shaping decisions around how companies are selecting CIPP materials for use in their products.

1. Professionals are seeking styrene emission mitigation solutions

Professionals representing municipalities and engineering firms are increasingly seeking solutions for styrene fume emissions. During projects, styrene can pose concerns when it is activated during the curing process, emitting hazardous vapors as a byproduct that pose health risks to those working the job and those in its vicinity.

Haartz's HP2 Styrene Barrier is a proven solution, with testing confirming that the product reduces the total amount of styrene emissions by more than 99%. Trenchless Technology went into great detail about styrene and mitigation using products like HP2 Styrene Barrier in their article titled Styrene Barrier Products – A CIPP Solution to Address Styrene Emissions.

2. The market for laterals is growing

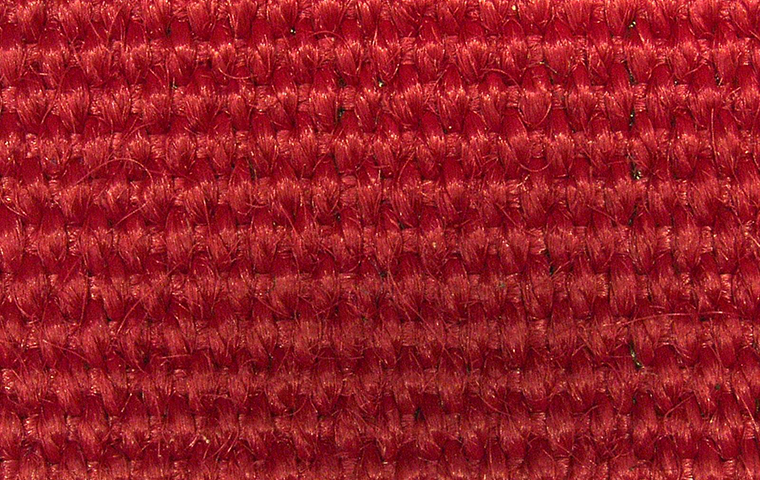

The CIPP lateral rehabilitation market is growing, as are the options available to installers who want to offer high-quality solutions. Professionals expressed interest in the growth of these solutions, as well as their general availability.

At Haartz, we offer a wide variety of CIPP materials that are designed for relining gravity-fed sewer lines, including lateral projects. Our HP2 Laterals lateral products provide a tough and reliable high hoop elongation liner and are compatible with a broad range of resins and inversion methods. Its thickness can be specifically tailored to suit the unique needs of any project and the material is pin-hole free.

3. There is a need for unique solutions

No single pipe-relining project is the same and professionals were clear about this in their feedback. The industry is seeking new effective lining solutions for various applications in gas lines, potable pressure lines and more.

If you missed us at No-Dig this year, reach out now and tell us about your unique needs. Our team would love to discuss how our or HP2 product lineup can help. We are uniquely positioned to develop innovative solutions. We draw from our over 100 years in the textile extrusion coating business, as well as our textile substrate and polymer knowledge, to tailor our products to meet the unique solutions of any job.

We look forward to seeing everyone for No-Dig next year in Denver.