EMPEL™ is a patented environmentally friendly sustainable high-performance fabric finishing technology. Utilizing a water-free application process and non-toxic chemistry, EMPEL delivers enhanced water repellency, finish durability, total breathability and soft hand feel, compared to traditional finishes.

EMPEL is a patented environmentally friendly sustainable high-performance fabric finishing technology. Utilizing a water-free application process and non-toxic chemistry, EMPEL delivers enhanced water repellency, finish durability, total breathability and soft hand feel, compared to traditional finishes.

EMPEL completely transforms the environmental impact of textile finishing while offering unparalleled performance. Fabric production is the second largest water polluter in the world, quietly polluting trillions of liters of water every year. Traditional wet fabric production methods require significant energy to dry the fabric and generate waste streams that must be treated downstream. EMPEL is safe, PFC free and independently certified by Oeko-Tex® to meet or exceed global safety standards. The EMPEL water-free process eliminates water pollution caused from fabric finishing.

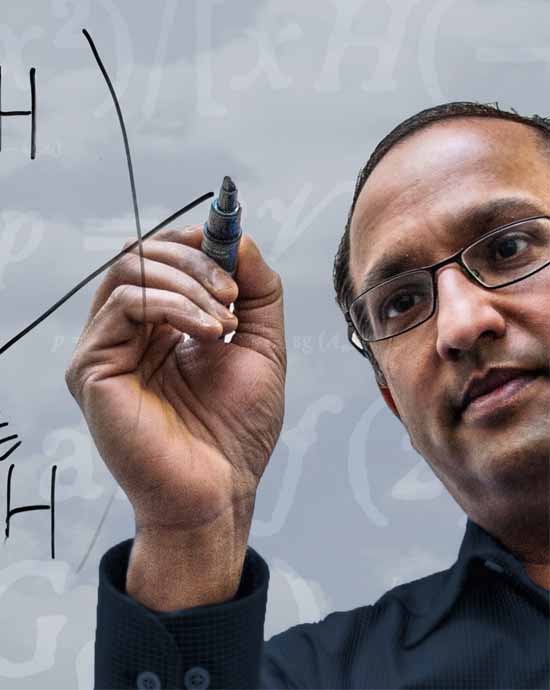

Traditional wet finish water repellent treatments stick chemistries unevenly between the fibers. These non-uniform coatings quickly wet out, wash off and cause fabrics to feel stiff. With EMPEL, the repellent chemistry uniformly wraps each individual fiber and is polymerized in place to create a durable molecular bond to the textile. Fabrics treated with EMPEL don’t wet out in heavy or prolonged rainstorms. The uniformly bonded chemistry ensures a highly repellent surface in even the most severe tests while not impairing the inherent breathability of the fabric.