Haartz unrivaled material: CIPP

For more than a century, Haartz has pushed the boundaries of coated textile performance. That expertise powers our HP² CIPP liners that are engineered for durability, flexibility and long-term structural integrity in trenchless pipeline rehab.

CIPP History

For nearly 30 years, the Haartz name has been highly trusted in the CIPP industry for high quality and outstanding performance. We offer a wide range of CIPP products through our High Performance Haartz Pipeliner → HP2 lineup.

We develop solutions that meet your unique requirements. Stemming from over 100 years in the textile extrusion coating business, our textile substrate and polymer knowledge combined with our supplier relationships are unparalleled making us one of the best and most reliable CIPP coated felt suppliers in the industry. We are uniquely positioned to help you solve problems you might not think are solvable.

Frequently Asked Questions:

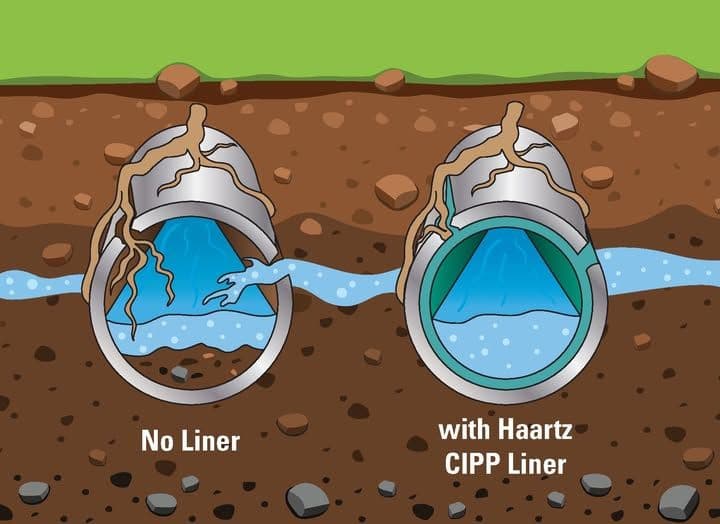

What is CIPP lining?

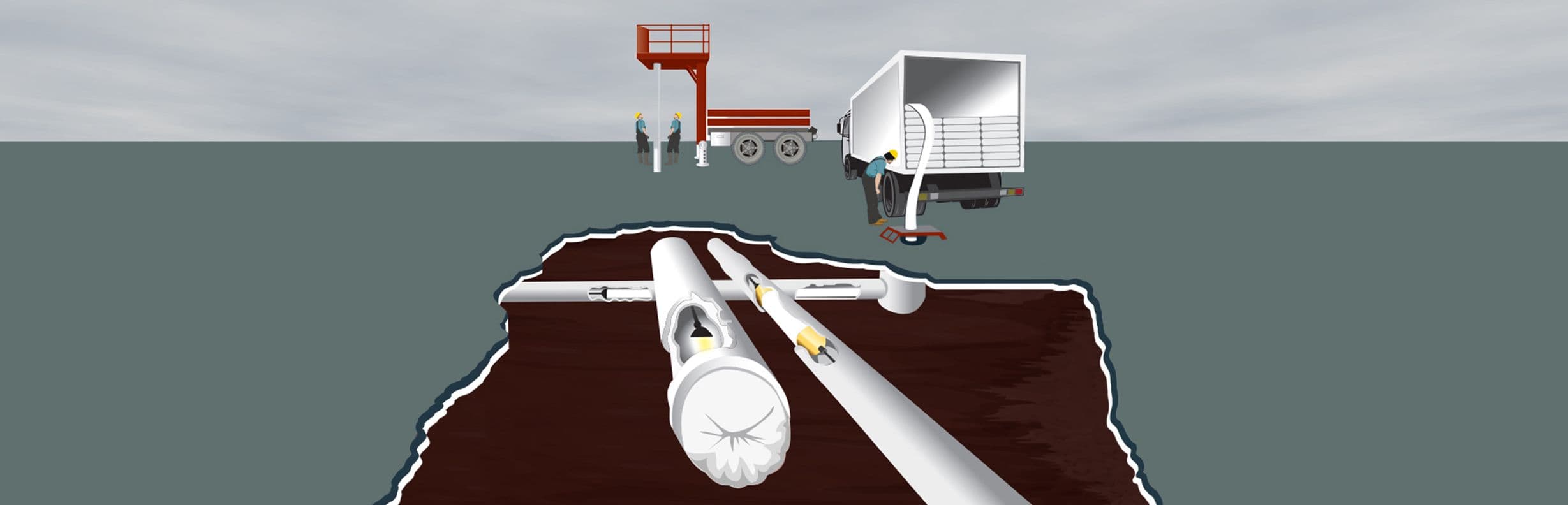

Cured-in-place pipe (CIPP) is a trenchless method for rehabilitating underground pipes. A flexible liner, saturated with a resin, is inserted and inflated to fit snugly against the host pipe. The resin then cures, creating a durable new pipe inside the old one.

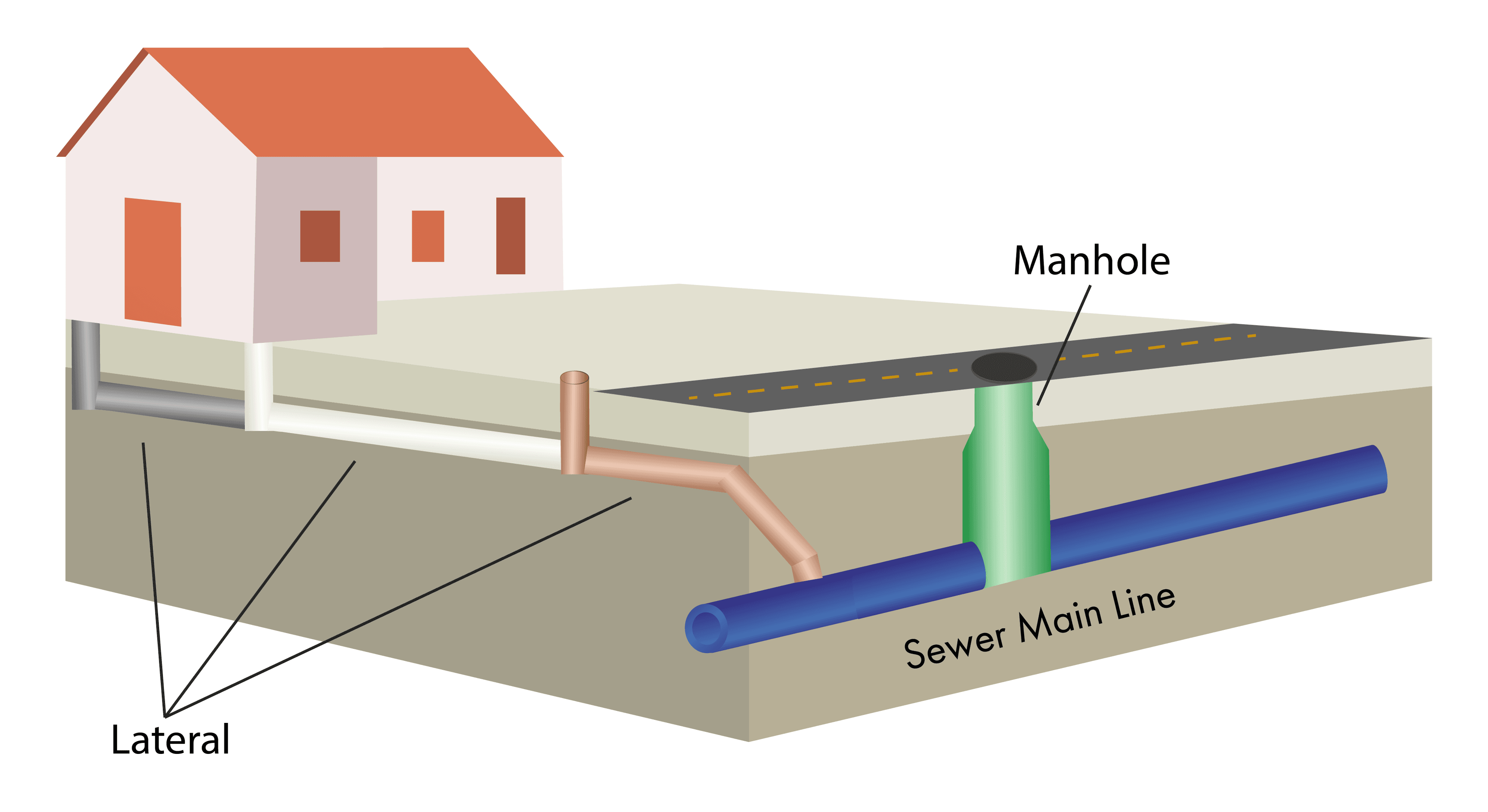

What type of CIPP pipe lining applications can Haartz’s products be used for?

Haartz's CIPP materials are designed for relining gravity-fed sewer lines (mainline and lateral pipes) and sewer access points (manholes).

What is that smell?

The smell comes from styrene, a chemical used in CIPP resins. Specialized coatings like Haartz’s HP2 Styrene Barrier act as a barrier to contain these vapors, creating a safer and more pleasant work environment.

Have more burning questions? Please contact us to learn more about our innovative CIPP process