Engineered Laminates

Your Vision, Our Innovation, Custom Solutions

Innovative Solutions

Haartz partners with businesses across diverse industries to develop high-performance laminates that deliver exceptional results.

ProTact by Haartz®

Product Applications

Durability

Built to last in demanding environments with solution-dyed fabrics and advanced coatings.

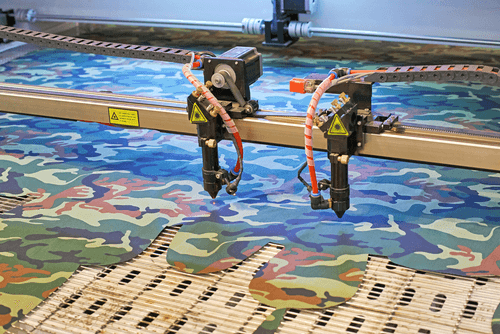

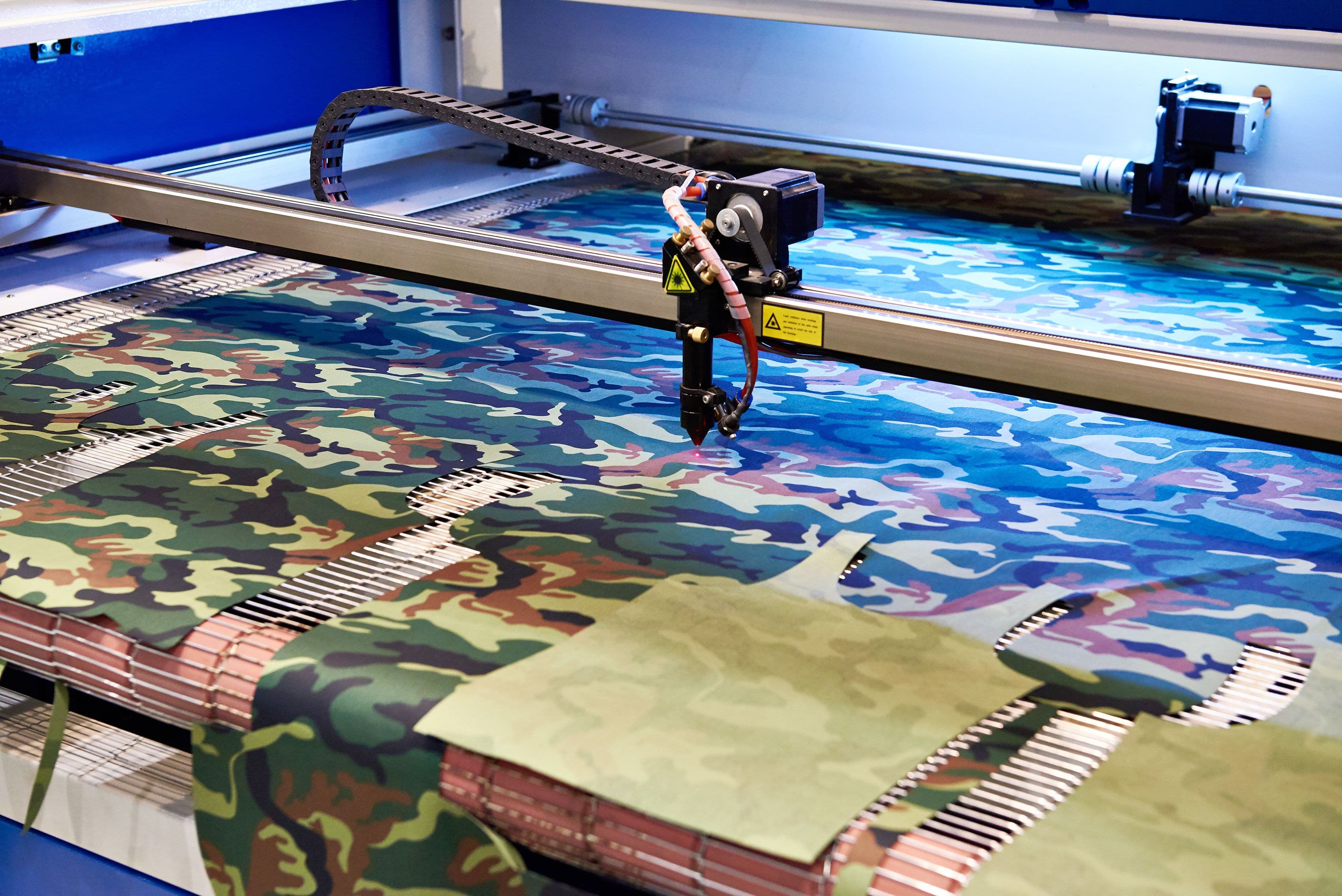

Processability

Easy to laser-cut, sew, or weld for versatile manufacturing.

Functionality

Offers flexibility, delamination resistance, and can be enhanced with non-slip or waterproof features.

ProTact Technical Data

| Material Type | Nylon Laminate |

| Weight (ASTM D751) | 21 OSY |

| Abrasion Resistance (ASTM 3884) | 700 min cycles |

| Adhesion (ASTM D751) | 16.5 LBF / 2 in. |

| Cold Resistance (ASTM D751) | Passes -40 C |

| Colorfastness to Crocking (AATCC 8) | Passes 5/5 (dry / wet) |

| Flex (ASTM D2097) | 10,000 min cycles / min |

| Hydrostatic (ASTM D751) | 72.5 PSI |

| Tensile (ASTM D751) | 816/699 LBF (warp/fill) |

| Tongue Tear (ASTM D2261) | 42/36 LBF (warp/fill) |

| Trap Tear (ASTM D5733) | 45/35 LBF (warp/fill) |

| Grade | Mil-Spec |

| Compatible w/ resins | Yes |

| Breathability | No |

| DWR Finish | Yes |

| Processing | Laser, Sewn, Welded |

| Material Type | Nylon Laminate |

| Weight (ASTM D751) | 24 OSY |

| Abrasion Resistance (ASTM 3884) | 700 min cycles |

| Adhesion (ASTM D571) | 17 LBF / 2 in. |

| Cold Resistance (ASTM D751) | Passes -40 C |

| Colorfastness to Crocking (AATCC 8) | Passes 5/5 (dry/wet) |

| Flex (ASTM D2097) | 10,000 cycles / min |

| Hydrostatic (ASTM D751) | 72.5 PSI |

| Tensile (ASTM D751) | 952/953 LBF (warp/fill) |

| Tongue Tear (ASTM D2261) | 71/75 LBF (warp/fill) |

| Trap Tear (ASTM D5733) | 194/162 LBF (warp/fill) |

| Grade | Mil-Spec |

| Compatible w/ resins | Yes |

| Breathability | No |

| DWR Finish | Yes |

| Processing | Laser, Sewn, Welded |

| Material Type | Nylon Laminate |

| Weight (ASTM D751) | 15.1 OSY |

| Bond (ASTM D751) | 41 Newtons (Warp) |

| Bond (ASTM D751) | 31 Newtons (Fill) |

| Elongation @ 267N (ASTM D5034) | 34% (Warp) |

| Elongation @ 267N (ASTM D5034) | 51% (Fill) |

| Flex (ASTM D2097) | Pass |

| Thickness (ASTM D751) | 0.65 MM |

| Trap Tear (ASTM D5733/D117) | 326 N (Warp) |

| Trap Tear (ASTM D5733/D117) | 259 N (Fill) |

| Tongue Tear (ASTM D2261) | 184 N (Warp) |

| Tongue Tear (ASTM D2261) | 177 N (Fill) |

| Tensile (ASTM D5034) | 1716 N (Warp) |

| Tensile (ASTM D5034) | 1579 N (Fill) |

| Material Type | Nylon Laminate |

| Weight (ASTM D751) | 16.3 OSY |

| Bond (ASTM D751) | 32 Newtons (Warp) |

| Bond (ASTM D751) | 31 Newtons (Fill) |

| Elongation @ 267N (ASTM D5034) | 47% (Warp) |

| Elongation @ 267N (ASTM D5034) | 55% (Fill) |

| Flex (ASTM D2097) | Pass |

| Thickness (ASTM D751) | 0.55 MM |

| Trap Tear (ASTM D5733/D117) | 389 N (Warp) |

| Trap Tear (ASTM D5733/D117) | 326 N (Fill) |

| Tongue Tear (ASTM D2261) | 207 N (Warp) |

| Tongue Tear (ASTM D2261) | 204 N (Fill) |

| Tensile (ASTM D5034) | 4571 N (Warp) |

| Tensile (ASTM D5034) | 3512 N (Fill) |

• Reach and Certified Berry Compliant material available.

Popular constructions are kept in stock in both the US and Europe, to ship quickly for low minimum quantity orders.

Approved to use Multicam® and other camouflage patterns, including Tiger Stripe and M81.

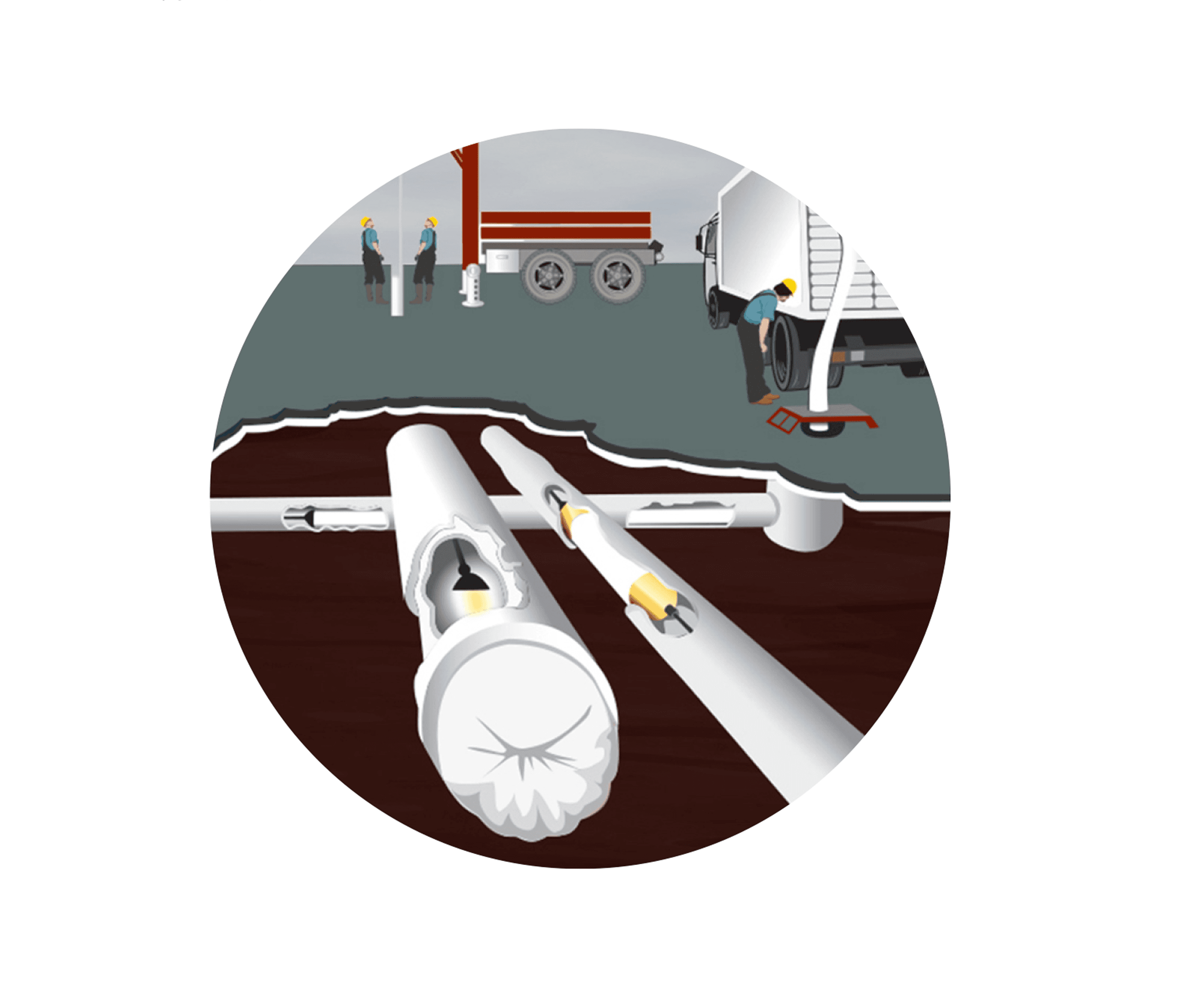

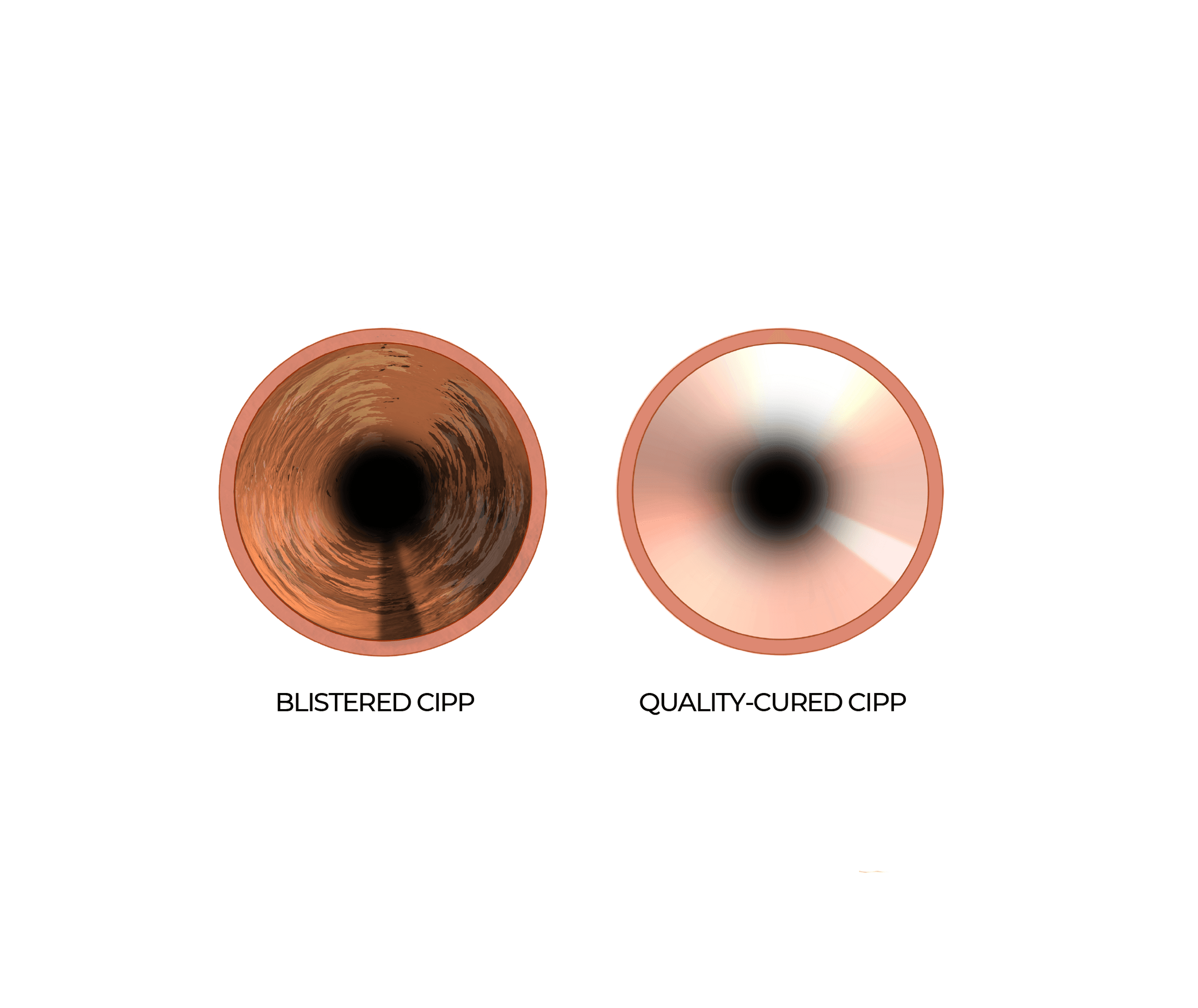

Cured in Place Pipeliner (CIPP)

Product Applications

CIPP Technical Data

| Barrier Type | Thermoplastic Urethane (TPU) |

| Barrier Thickness | 9-13mils (0.23-0.33mm) |

| Benefits | Air or Water Inversion |

| Hot Water or Steam Curing | |

| Ease of Wet Out and In-Field Patching | |

| Gravity Fed Manline Applications |

| Barrier Type | Thermoplastic Olefin (TPO) |

| Barrier Thickness | 17 mils (0.4mm) |

| Benefits | Ease of Inversion |

| Hot Water or Steam Curing | |

| Withstands abuse during installation | |

| Blister Resistand during Steam Curing | |

| Gravity Fed and Main Line Applications |

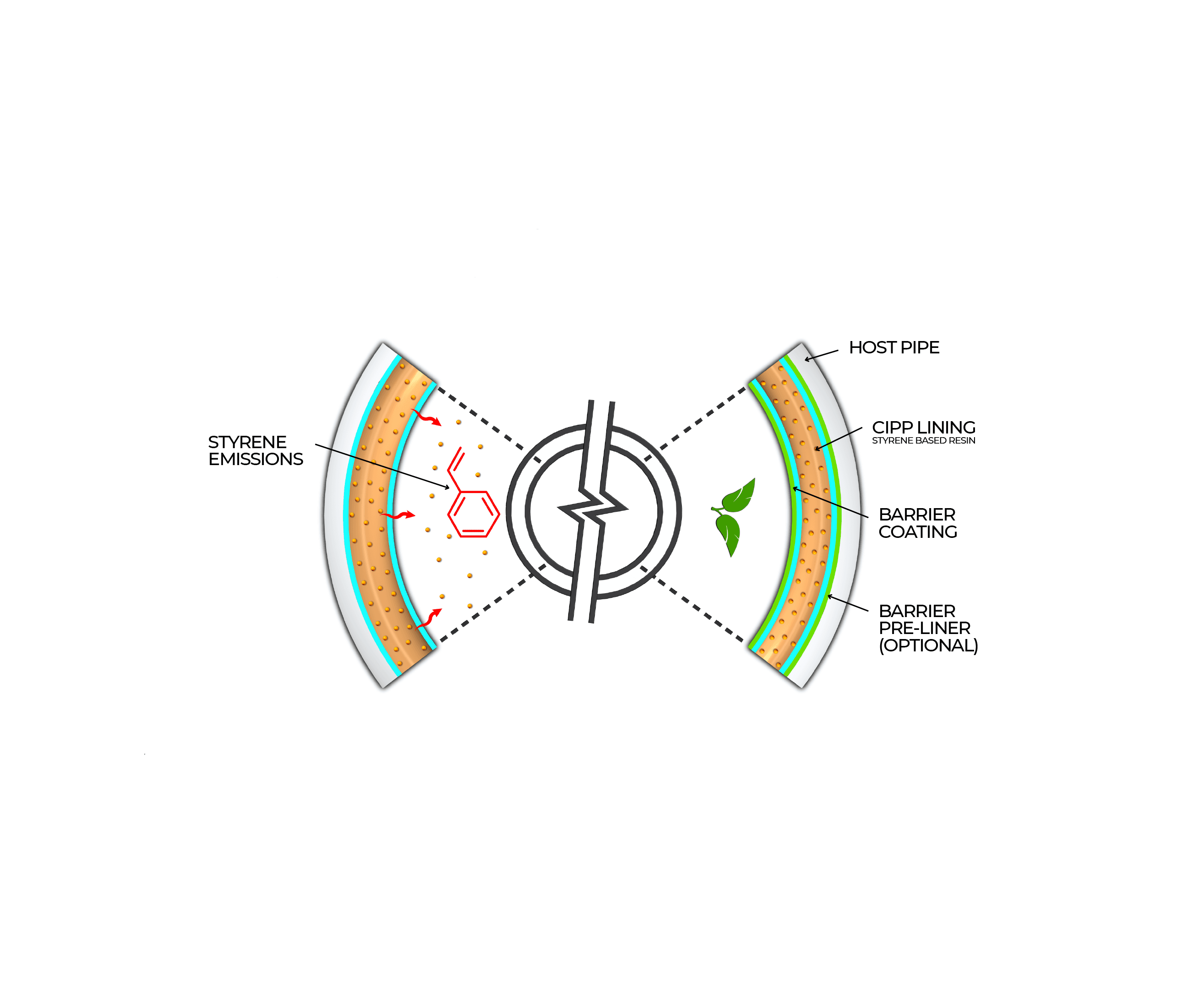

| Barrier Type | Proprietary |

| Barrier Thickness | 7mils (0.18mm) |

| Benefits | Pull-In and Inversion |

| UV, Hot Water, Steam Cured | |

| Low Styrene Emission (<0.5ppm) |

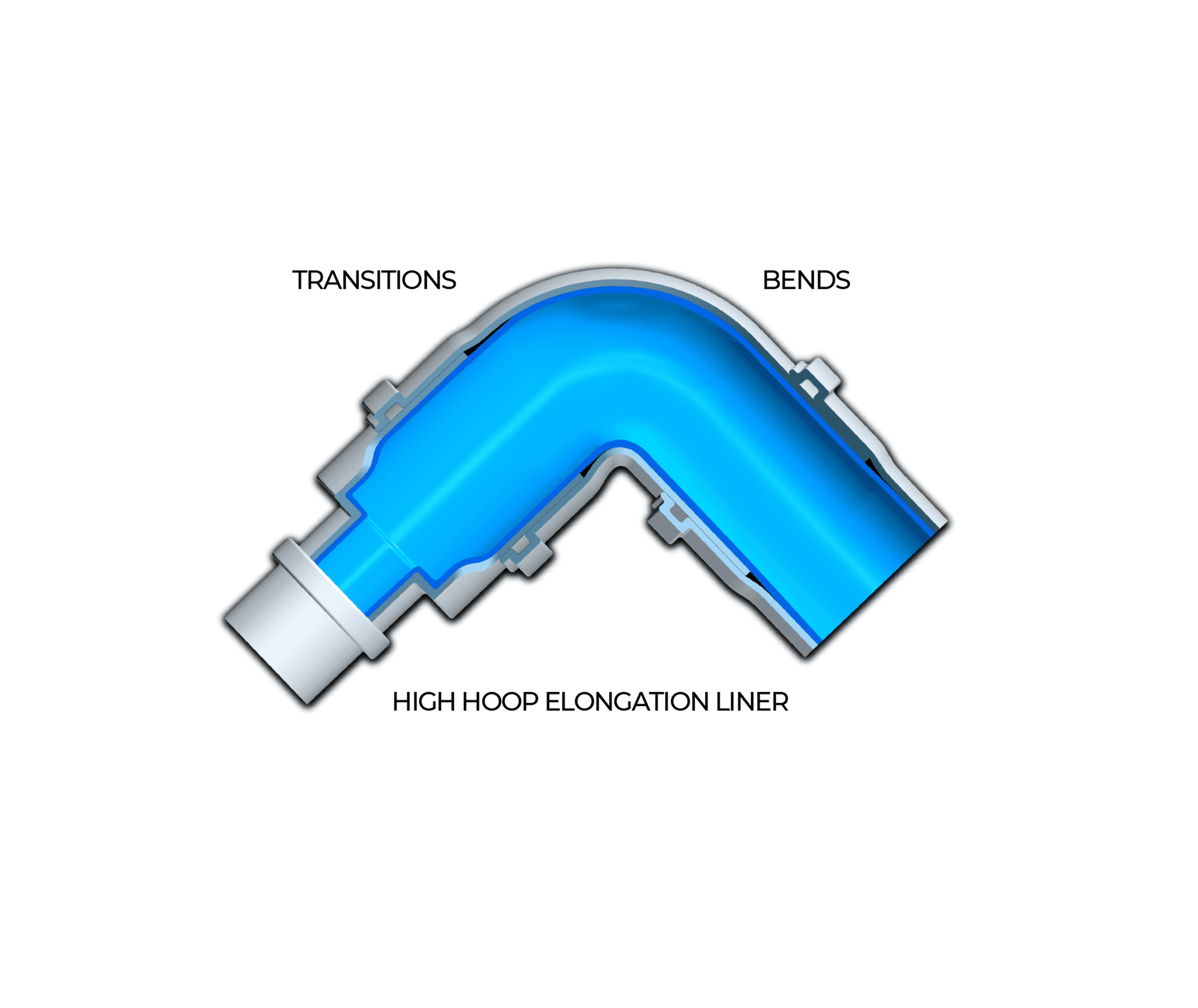

| Barrier Type | Polyvinyl Chloride (PVC) or Thermoplastic Urethane (TPU) |

| Barrier Thickness | 9-14mils (0.23-036mm) |

| Benefits | Air or Water Inversion |

| Ambient or LED Cured | |

| Compatible with a broad range of resins including: Polyester, Vinyl Ester, and Epoxy | |

| Bends >45° and 4-6" Pipe Diameter Transitions | |

| High Hoop Elongation and Axial Control |

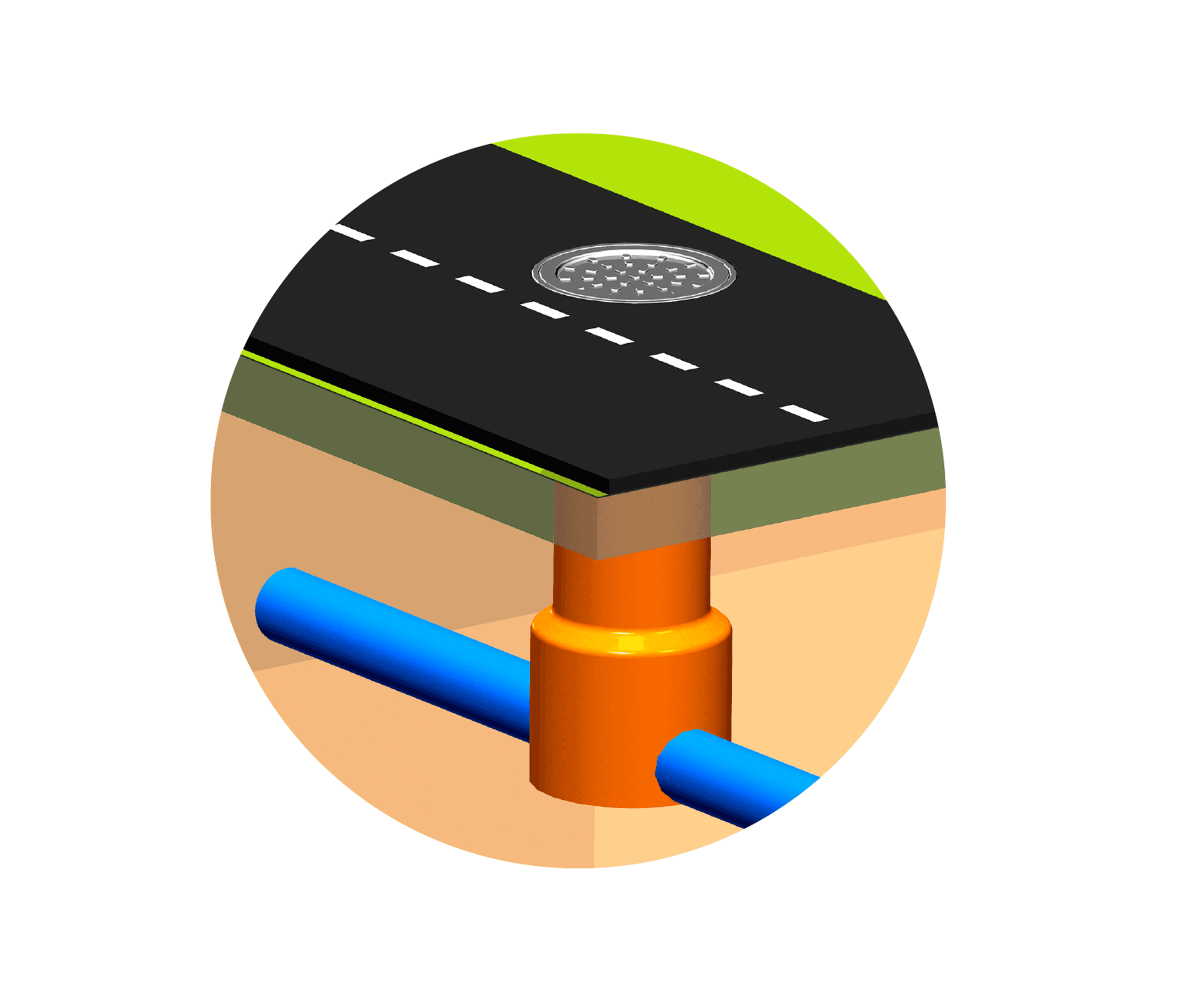

| Barrier Type | Polyvinyl Chloride (PVC) |

| Barrier Thickness | 21mils (0.53mm) |

| Benefits | Hot Water or Steam Cured |

| Blocks Corosion of critical infrastructure |

Market Solutions

Leading the way in durable technical materials that solve complex challenges across multiple industries.

Soft Sided Luggage

Custom PVC-coated fabrics for luggage and handbags, blending style with durability.

Soft Sided Luggage

Custom PVC-coated fabrics for luggage and handbags, blending style with durability.

Marine Canopy

Durable, long-lasting material for marine canopies and boat covers that resists mold and mildew.

Marine Canopy

Durable, long-lasting material for marine canopies and boat covers that resists mold and mildew.

Footwear

Performance, waterproof material for footwear that resists abrasion and provides long-lasting comfort.

Footwear

Performance, waterproof material for footwear that resists abrasion and provides long-lasting comfort.

Industrial Fabrics

Industrial seals custom-engineered, combining fabric and rubber for superior strength and flexibility.

Industrial Fabrics

Industrial seals custom-engineered, combining fabric and rubber for superior strength and flexibility.