At the 2024 SHOT Show Supplier Showcase, we had the opportunity to engage with manufacturers from across the law enforcement, military and tactical gear industries. Through these conversations, we’ve identified four trends shaping decisions around how companies are selecting specialty laminates like our ProTact by Haartz™ material for use in their products.

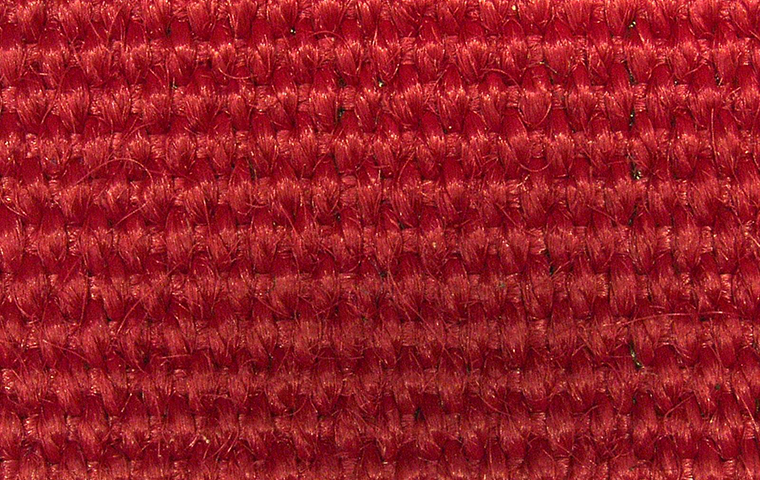

Cordura laminates are high-performance, durable woven and coated nylon fabrics renowned for their durability and versatility. While Cordura is a widely-used, high-end yarn, using it with a laser-cutting application is gaining popularity in military, law enforcement, medical and commercial armor plate carriers, chest rigs, pouches and accessories. Laser cutting material like Cordura avoids the risk of fabric tearing and allows for better customization when crafting the material into varying shapes and sizes.

Haartz has been laser cutting Cordura for years for custom designs for soft-sided luggage and handbag applications. We’re building on that experience to offer the same technology to our ProTact line to provide the highest quality fabric with the cleanest look and most versatile functionality.

2. There’s demand for both old and new camo patterns

While some patterns have fallen out of broader use over time, a need for them still exists and companies supplying material must ensure they maintain a balance between producing sizable quantities of fabric in high-demand patterns as well as keeping classic patterns available.

Haartz recognizes that each customer has specific design parameters including needs for various patterns. That’s why we developed ProTact with adaptability in mind. It can be customized with various material constructions and properties and can conform to a wide range of patterns, including each manufacturer's unique proprietary patterns and prints. We keep the most popular patterns like MultiCam or classic Vietnam Tiger Stripe in stock and do our best to provide reasonable turn-around times for custom orders.

3. Materials must be adaptable, functional and durable

Manufacturers expressed an interest in materials that excelled in modularity, compatibility, functionality and durability. With more than 100 years of expertise, Haartz excels in providing materials that are easy to cut, sew and integrate into various products while maintaining exceptional durability.

Our ProTact laminates have been developed with the most durable solution-dyed nylon fabrics available on the market using advanced coating systems that are optimized for application-specific enhancement properties. This manufacturing process ensures that the final products meet the rigorous standards expected in demanding environments.

4. Customization is Key

Lastly, manufacturers expressed that the availability and customization of coated fabrics and laminates were critical factors for satisfying the evolving needs of this market.

By manufacturing ProTact in the United States, Haartz maintains a robust supply chain that ensures customers receive their products on time with wide availability. ProTact can also be enhanced with flame retardant, electrostatic dissipative and other functional properties. Additional surface coatings can also be included for non-slip or printable surfaces.

Haartz remains at the forefront of innovation and builds on its 100+ years of coated fabric expertise to craft superior products for its customers. By paying attention to emerging trends and continuously enhancing its product offerings, the company can meet its customers' evolving needs by supplying superior technical laminates specifically developed to exceed the performance standards of coated fabrics used in military and tactical gear applications.

Unable to connect with us at SHOT Show? Contact us today.