What is CIPP lining?

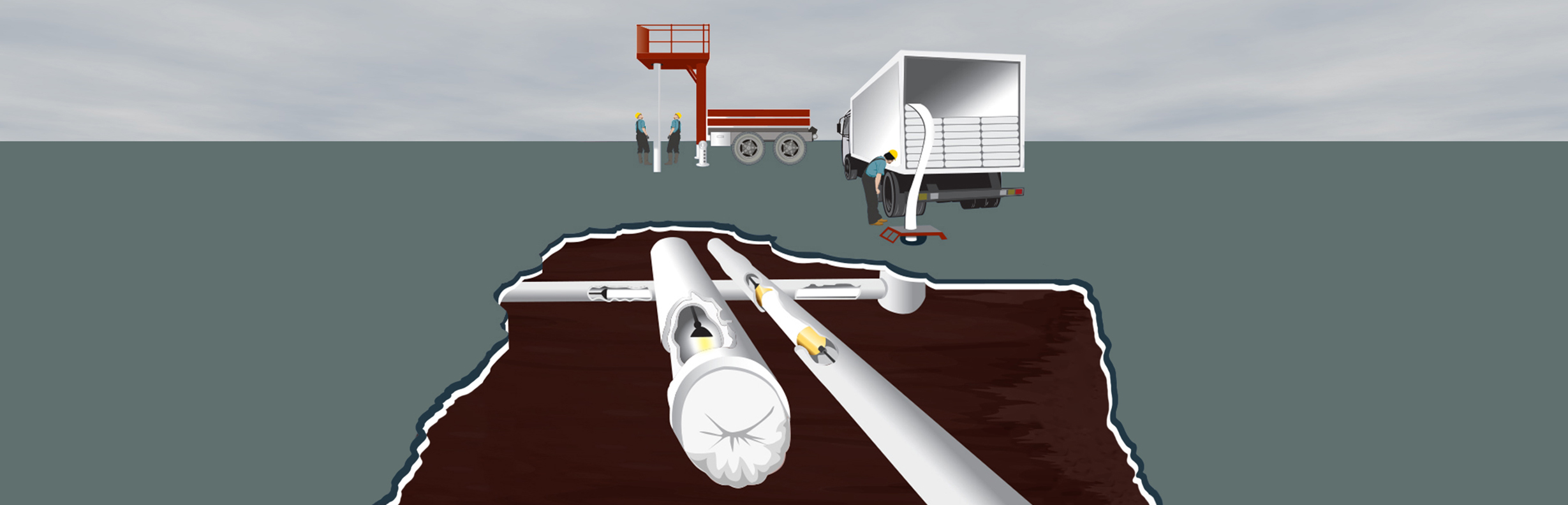

Cured in place pipe (CIPP) is a trenchless, in-situ rehabilitation method for underground pipes. CIPP companies use styrene based thermoset resins to create a flexible liner wet-out in epoxy and resin. The liner is inserted into the host pipe and inflated so that it fits perfectly snug against the existing pipe. The styrene based thermoset resins are activated during the curing process. Once hardened, the new lining will provide a long-lasting barrier and renew the pipeline to like-new condition.

What type of CIPP pipe lining applications can Haartz’s products be used for?

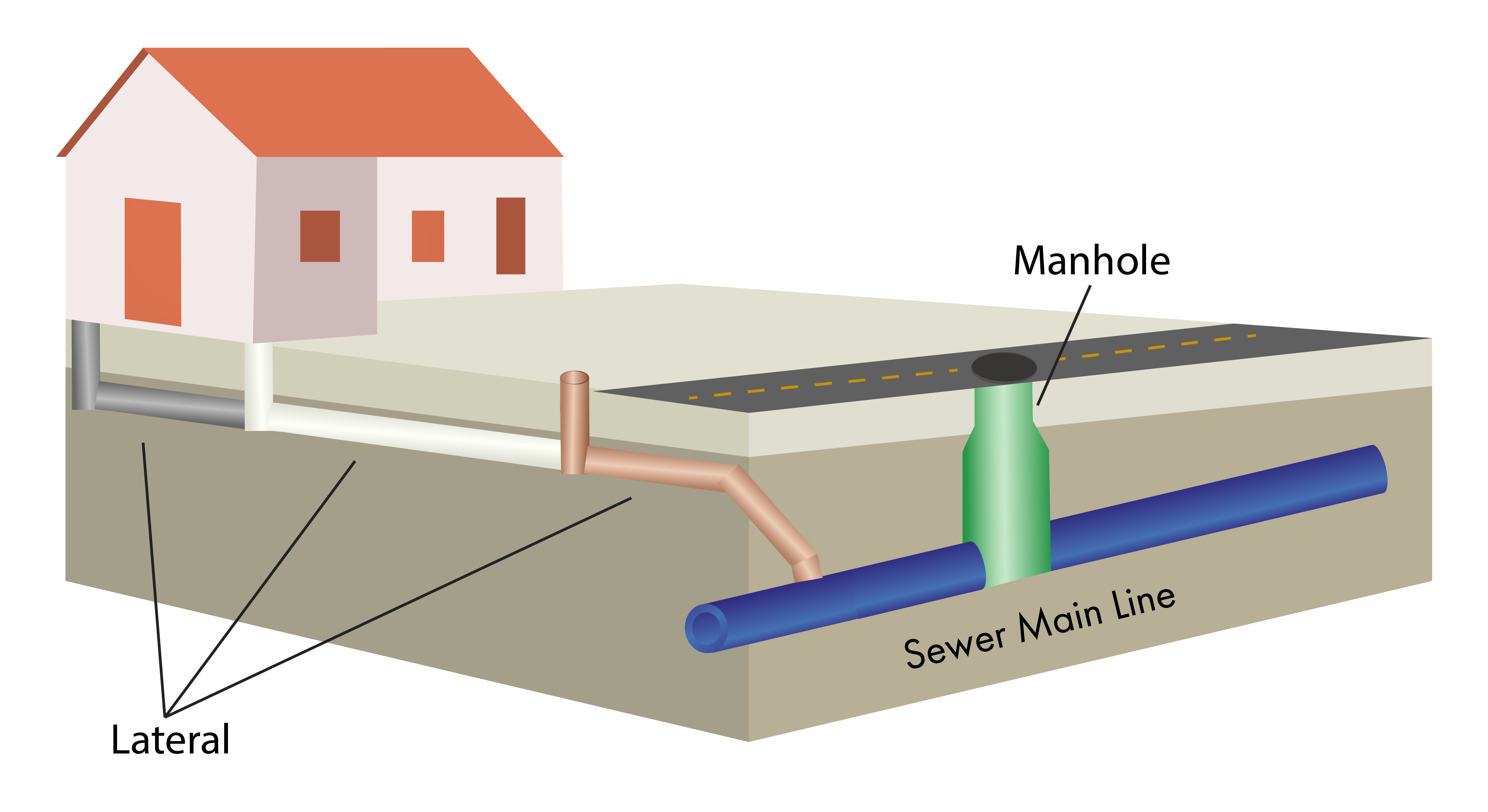

Haartz’s CIPP materials are designed for relining gravity-fed sewer lines (Mainline and Lateral pipes). Our materials can also be used to reline sewer access points (manholes).

What is that smell?

Styrene is commonly used as a reactive diluent in CIPP resins. Styrene volatile organic compounds (VOCs) can easily be detected by humans in concentrations under 0.5 ppm. Styrene VOCs from uncured resin can break through traditional CIPP coatings during wetout, in transit, and installation. Designed properly, CIPP liner coatings such as HP2 Styrene Barrier, can act as an effective barrier and keep the styrene vapors contained to remain in the liner to prevent potential human exposure, making for a safer and more pleasant work and living environment. Municipalities can benefit from the use of HP2 Styrene Barrier in that residential complaints can be potentially eliminated.

Does Haartz offer potable water CIPP products?

We can design products to meet your specific needs for this situation. Please contact one of our CIPP experts for more information.

Can you repair your pipes by cleaning or pouring certain chemicals?

No. Trenchless technology pipelining is the easiest, cheapest, least obstructive way to actually repair pipes in a meaningful and lasting way. Damage from invading tree and shrub roots cause cracks leading to infiltration. New pipelining will provide a strong barrier and protect the inside of your pipes from these issues.

How does blistering occur and can it be prevented?

Blistering can occur during steam curing when installers overheat a TPU-based material. TPU liner can be steam cured successfully, without blisters, by following manufacturer’s guidelines. Our TPO lining offers a more blister resistant CIPP formulation.

How much does CIPP lining cost?

CIPP lining offers major savings compared to excavation and pipe replacement. Because CIPP requires fewer resources and labor, customers can save up to 75% in costs compared to pipe replacement.

What’s the difference between Slip vs CIPP lining?

Slip lining is a rehabilitation method where a new rigid carrier pipe is pulled through a larger host pipe. Installers then grout the space between the two pipes and seal the ends. Slip lining results in a smaller cross-sectional area for pipes due to the space required for grouting. Because slip lining uses a premade, rigid carrier pipe, it can be difficult to adapt to unusually shaped pipes. CIPP lining better adapts to the form of its host pipe due to the flexibility of the liner and the in-place curing process.

When shouldn’t you use CIPP?

CIPP offers a great, versatile solution for renewing municipal, industrial, and commercial infrastructure. However, there are some occasions when other methods will better address your rehabilitation needs:

- When pipes need to be upsized. Excavation or trenchless static pipe bursting works best for expanding a pipe’s diameter. Static pipe bursting can increase the diameter of a host site without excavation. This method works especially well in areas where the environment is especially sensitive. No matter the method, upsizing pipes will be a large undertaking that requires significant planning.

If I have a problem I need to solve, can Haartz design a product to meet my specific needs?

Haartz is much more than a toll coater. We develop solutions that meet your unique requirements. Stemming from over 100 years in the textile extrusion coating business, our textile substrate and polymer knowledge combined with our supplier relationships are unparalleled. We are uniquely positioned to help you solve problems you might have considered unsolvable.