A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

There are many terms listed here in addition to specialized ones previously mentioned (in italic type). Besides technical terms, trade names are listed where the name signified a certain type of top material, as was often the case. Where the production time period for certain trade names is known, that has been furnished.

ARTIFICIAL LEATHER

Surface coated fabric whether used for top material, upholstery or for auto interior trim. Generally, these were pyroxylin-coated fabrics. The term was pretty much obsolete after 1950, but during later years of use, was cleverly modified to “art leather”.

BINDING and WELTING

Various forms of strip material used to trim out tops at the header bow, rear bow and in other forms of soft-trim edge work. Usually made up from lightweight coated fabrics to complement or correspond with the top material. The various forms of these binding have different names and serve varied functions in soft-trim work on vintage cars:

Single and double edge-fold bindings were used for trimming exposed edges of tops or other soft-trim parts. Double edge-fold binding was also used for trim work on front and rear bows of folding tops until supplanted by “hidem”, “locktite” and “wireon” weltings from the mid-1920s onward.

Hidem welting was introduced in the early 1920s for use on the front and rear bows of folding tops, where ends of material were tacked to the bows. Use of the hidem (a contraction of “hide them”) welting enabled a trimmer to conceal these lines of tacks, giving a nicer finished appearance. Also serving the same applications were Locktite and Wireon weltings, both introduced in the early 1920s. Wireon was originally made in several configurations depending on where it was used on the car-roof periphery. As suggested by the name, these were wire-reinforced, beaded profiles for use in vehicle soft trim work. They had a semi-round flap that folds down to conceal tack heads and present a decorative or functional look to the edge work at the front and rear top bows.

BOOT

A fitted cover to conceal and protect a folded-down soft top. The boot material would normally match the top material. For cars made in high volume, a lower-cost but matching fabric would likely have been used. For cars made in low volume, the maker frequently used additional yardage of the top material.

BOW DRILL

Uncoated inner or lining cloth used for the listing, or attachment and wrapping of the top bows. This cloth corresponds with the lining of the top material, regardless of whether it is technically a drill weave.

|

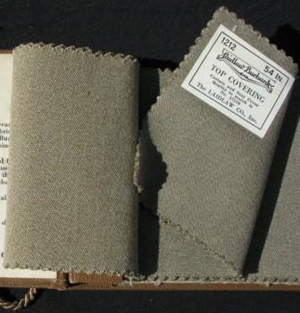

BURBANK A tightly woven cotton duck cloth made as an uncoated fabric for automotive soft trim. It was sold in various grades for top material, side-curtain material, and for seat coverings. Offered as early as 1908, it was a particularly respected brand of top material during the 1920s. Usage diminished in the 1930s probably because automotive standards for waterproof materials exceeded the performance of Burbank. It was very expensive, too. The cloth was made in Great Britain and imported into the United States by Laidlaw & Co. of New York City. The name “Burbank” also applies to a linen-like embossing pattern used for some vinyls after 1975. |

|

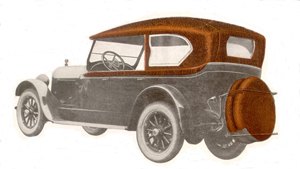

CALIFORNIA TOPS Beginning about 1916, open touring cars could be fitted with rigid tops, open or with removable windows on the sides, for use in cooler seasons. Different makers had their own names for this feature, but because the concept was popularized by the coachbuilding firm Walter Murphy Company in Pasadena, CA, theirs and others came to be known as California Tops. Makers of these accessories pitched the idea that the California Top could be used in the cooler months of the year, while it could be replaced by a traditional folding soft-top in the warmer months. Some carmakers offered these as an option with their touring cars. Many aftermarket producers of California Tops finished them with coated-fabric roof covers for enhanced styling, typically using artificial leather for the covering. Given some of the styling trends of the time, artificial leather styles with a Spanish Print effect were popular in this application. |

|

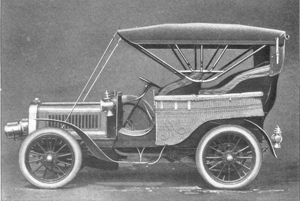

CAPE CART TOP A top frame construction from the earliest days of the auto industry. Adapted from rear-entrance horse-drawn carts, the true “Cape Cart Tops” were used on early rear-entrance tonneau bodies on cars in the pre-1907 era. These tops pivoted on single attachment points on each side of a car, to which the top bows were attached. Loose usage of this term mingled its use with extension tops, more typically seen on open touring cars once side door tonneaus came into use by the automobile industry (the tonneau referred to the rear seating area of a touring car). |

CHASE

L.C. Chase & Co. acted as selling agents for a consortium of New England weaving mills and a fabric coating firm from the beginnings of the auto industry until about 1940. They offered surface-coated materials (under the Drednaut trade name, but sometimes called “chase” leather) and rubber-combined cloth materials (under the trade name Wexford), as well as other automotive textile products. Successor firms continued in the business for a few more decades. L.C. Chase & Co. headquarters were in Boston during most of their existence.

|

DECKING OR DECK MATERIAL Prior to the advent of all-steel tops on closed-bodied cars, the flat “deck” of the rooftop was covered by a coated, painted, or treated fabric panel. Typically a surface-coated fabric was used on passenger cars and enamel-painted duck or oilcloth used on commercial vehicle bodies. Some of the more expensive car bodies wore a full roof cover, with either a surface-coated deck material or a three-ply cloth topping. The surface-coated materials for this application used some embossed grains common to convertible top materials, and some that were unique to deck and roof cover fabrics. |

DOBBY WEAVE

This textile industry term refers to any cloth with geometric patterns woven into the cloth. The notable example in top material is the lining cloth with a criss-cross pattern used in convertible topping for Mercedes-Benz and other German cars, especially in the last couple of decades. This kind of backing cloth was in use by the early 1930s in Germany.

DOUBLE TEXTURE

A now-extinct top material construction. In automotive use, it generally refers to a surface-coated fabric of four layers (See the General Terms and Types section and Figure 3). Use of this term prior to 1920 referred to three-ply, rubber-combined cloth constructions, the term having originated as such prior to 1900.

DREDNAUT

Surface-coated top material produced by L.C. Chase and Co. of Boston, MA from 1914 through the early 1930s.

DRIDEK

Surface-coated top material manufactured by the L.J. Mutty Co. of Boston, MA from about 1915 through 1930.

DURABLE

An all-cotton, rubber-combined cloth top fabric produced by Haartz for many years. Discontinued from production in 1994.

DURATEX

Trade name for surface-coated pyroxylin fabrics made by the Duraleather Company of Newark, NJ in the 1915 to 1935 period. Some production perhaps served the market for tops of open and convertible cars. According to period advertising, Duratex was certainly made for roof deck and cover on closed cars, fabric-bodied cars under Weymann and Childs licenses in the 1920s, and for artificial leather for automotive interior trim.

ENAMELING DUCK

A “loosely” woven light duck cloth (8 ounces per square yard or lighter) that was stretched over the top deck of early closed automobile and truck bodies and then painted with enamel paint. Depending on the top frame construction, other, untreated textiles might be used to add support and insulation underneath the painted duck. Because enameled duck could not withstand flexing, it was only used for roof covering on closed body vehicles.

|

EXTENSION TOPS The extendable, folding top mechanisms were prevalent on touring car tops through most of the 1905 to 1915 time period. When the early auto industry abandoned rear-entrance doors for the back seat area, using side doors instead, the extension top allowed easier clearance from the bow legs than was possible with the earlier Cape Cart Tops. An extension top, in its down and folded position is pulled up and forward bows moved from the rear attachment points to a forward set mounted on or near the front seats of the car. This kind of top was replaced by the one-man top mechanism prevalent on open cars from around 1915 onward. |

EVERFLEX

British vinyl top material that had been popular and widely used in Europe for many years. This was a 2 ply vinyl offered in various color combinations on both exterior and interior sides.

FABRIC SKINNED BODIES

In the late Teens, two individuals developed and licensed technology for fabric skinned automobile bodies. Charles T. Weymann, based in Paris, France, is the best-known proponent of the idea. K.L. Childs in the USA offered a similar, patented idea in 1921. Weymann achieved the best success with European makers of custom or limited production coachwork and some British automakers. In 1926, Weymann opened the Weymann American Body Company in Indianapolis, IN, USA. Car bodies of these kinds used pyroxylin surface-coated fabrics for the exterior skin. The concept of fabric skinned bodies achieved limited acceptance in the 1920s in Europe and the USA but vanished in the USA during the Great Depression. For an excellent analysis of this practice, see A Century of Automotive Style, 100 Years of American Car Design by Michael Lamm and Dave Holls, Lamm-Morada Publishing Co., Stockton, CA, 1996-97, ISBN 0-932128-07-6, pages 46 through 48. Another useful reference is the Wikipedia entry for “Weymann Fabric Bodies”. Brand names of surface-coated fabrics used for this kind of work included Duratex, Fabrikoid, Meritas, and Zapon.

FABRIKOID

A pyroxylin surface-coated fabric made by a facility of the same name in Newburgh, NY from about 1900 into the 1960s. E.I. DuPont de Nemours bought the plant in 1910, offering Fabrikoid as a DuPont product thereafter. While some of this output was top material in earlier years, the production of upholstery leatherette (or artificial leather) dominated the later production of automotive soft trim fabrics under this trade name. The name “Fabrikoid” was sometimes used as a synonym for pyroxylin-coated fabrics, especially in connection with bookbinding materials. With the popularity of the so-called California Tops between 1915 and 1925, Fabrikoid was a preferred roof cover material.

FACE / FACING FABRIC

As used here, the term refers to the outside fabric or exterior surface of a top material.

FIBER BLEND

Cloth woven from blended multicolor (or multi-shade) fibers. Usually, one color dominates and the other imparts a highlighting effect.

GRAIN

The outside (facing) of surface-coated top materials usually have an embossed, decorative pattern. This embossed pattern is referred to as the grain. It might resemble a leather or animal hide surface, in keeping with the maker's desire to provide an artificial leather. In other instances, the grain might be a geometric pattern, or it might resemble a cloth or linen surface texture. Some of the more common grains encountered in soft-top trim materials are:

Bison - an animal-hide type of pattern

Cobra (Short) - a reptile-hide pattern, commonly used from ~1912 to ~1930

Colonial - an animal-hide pattern, extensively used in No. America for decades

Crush - an animal-hide pattern, used in the 1950s and 1960s (Jeep® tops)

Denim - a fine geometric pattern used for Jeep® vinyl tops since about 1970

Ford (model T) - a flattened “pebble” grain, currently replicated via Turf grain vinyl

Long / Long Cobra - reptile-hide pattern, enlarged version of Cobra grain 1915 - 1930

Monaco - a deep animal-hide grain common in Europe in the ‘50s and ‘60s

Pebble - a pebbly geometric pattern, most common 1915 to 1930

Pinpoint - a geometric pattern, see Standard grain

Sierra - a shallow and subdued animal-hide pattern for accessory materials

Standard - the Orig. Equipment “standard” during the era of vinyl soft-tops from about 1954 to about 1994. Also known as “diamond” or “pinpoint” grains. This is a geometric pattern made up of tiny, four-sided pyramids.

In addition to the soft-topping embossings noted, there were other grains used for deck and roof cover fabrics for pre-1940 closed cars. So, too, with the fabrics used during the North American vinyl roof cover craze from the mid-sixties through the seventies. Notable examples from that time are Laredo grain on Chryslers, Corsica and Valino grains on Fords and Elk, Levant, and Tuxedo grains on GM cars. (Incidentally, the Tuxedo grain saw use on deck fabric for GM-Fisher Body and Packard cars in the 1930s.) Yet another array of grains (with and without accompanying surface print patterns) were used on vinyl upholstery materials for cars. Likewise, other grains were used on some top decking materials from the 1920s and 1930s.

Embossing techniques improved over time. Prior to 1920, coated surface embossings were shallow and indistinct. Improved embossings gave a better surface appearance on toppings made in the twenties and thirties. Vinyl embossing yields much better depth or definition, so the modern-day surface-coated fabrics look better than their pre-1920 ancestors.

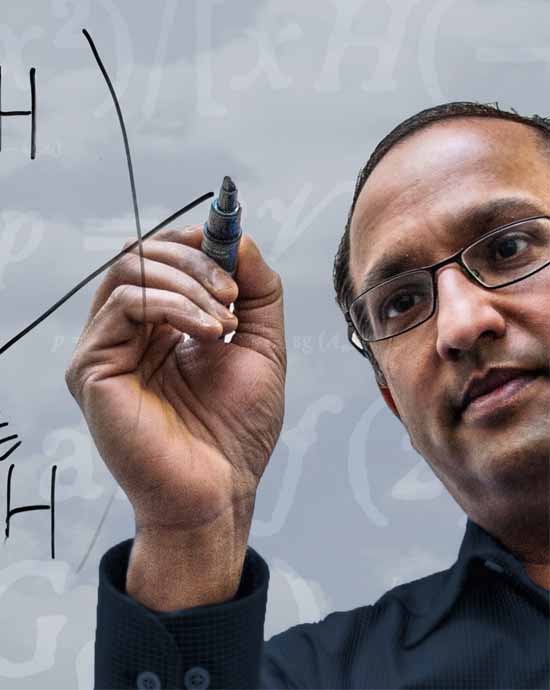

HAARTZ CLOTH

A generic term used in the vintage and specialty car field. The term is used more or less indiscriminately to refer to most any 3 ply cloth top material (although many people use the term for such goods using cotton fabric). We at Haartz don’t officially use the expression, but we’re honored by it!

HAPPICH

The German cloth top materials, marketed for many years by Gebruder (Brothers) Happich GmbH, were made by Rode and Schwalenberg GmbH. While offered under the Sonnenland® trade name since 1972, the Happich name is still associated with this material. It is also known among car enthusiasts as the “original German material”. See Sonnenland®.

HIDEM

A widely used category of top-bow welting. See Binding and Welting.

HYPALON

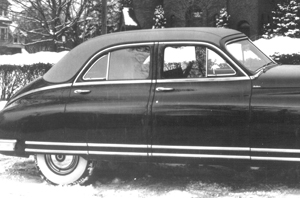

This was a synthetic rubber developed by DuPont. Haartz and DuPont offered this as a surface coating on line of top materials in the 1950s. While it had some advantages over vinyl, the latter proved superior in more ways. In the automotive industry, Hypalon material is best remembered as being used as roof cover material on Packard Caribbean hardtops in the mid-fifties. It was embossed with the so-called Crush grain.

JONARTS®

A trademark of Haartz used most prominently for the company’s premier rubber-combined cloth top materials from the late 1920s into the 1950s. A contraction of the founder’s name (John Haartz).

KHAKI CLOTH

Uncoated, tightly woven cotton duck cloth dyed a khaki shade. So-called number 8 duck (18 ounces per square yard) was better, and number 10 (about 14.7 ounces per square yard) used for low cost jobs. Khaki cloth was used for automobile topping prior to 1915, probably impregnated with a wax-based compound to enhance water repellency.

|

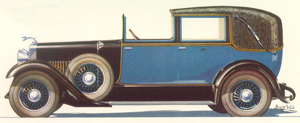

LANDAU TOP Originally used in reference to a feature on some formal horse-drawn carriages, the folding landau top was used in comparable coachwork for automobiles. After the grand era of custom auto bodywork in the 1920s and 1930s, the concept of a landau top changed from a functional feature on limited production car bodies to a decorative feature on higher-volume cars. Instead of a folding soft top over the rear seat of a formal town car, landau tops became a rigid, decorative roof cover for upscale sedans, especially after 1960. From about 1964 through 1985, this term came to refer to any vinyl roof-cover on sedans, promoted especially by Chrysler, Ford, and General Motors. Some of these were embellished with dummy landau bars: gently “S” shaped, chromed bars reminiscent of functional parts on the outsides of folding landau tops decades before. The landau top, in its later form, persists on the roofs of American stretch limousines and received further embellishment in the form of simulated convertible tops from about 1980 onward. |

LEATHERETTE

Surface coated material for tops, upholstery and interior trim on automobiles. Since the 1950s the term has been used more or less generically for all kinds of vinylcoated fabrics, and remains in active use. See artificial leather.

LINING

As used here, the term refers to the backing or inside surface of a top material. Besides referring to the inside surface of the topping itself, the term often applies to the additional lining of uncoated cloth inside the top frame and bows, functioning as a headliner. Tops with a separate liner inside the top frame have been available on some vehicles through all eras of automobile production, and back into the heyday of horse-drawn carriages.

MACKINTOSH

The term originated in reference to rubber-combined (3 ply) raincoat materials produced in the 1800s, and came into use generally for any kind of rubber-combined cloth fabric by 1900. With respect to auto top materials, it usually referred to those composed of cotton fabrics on both sides, but by the late 1920s such use of the term had ceased.

MERITAS

The brand name of automotive top materials made by the Standard Fabric Company in New Jersey prior to 1940. The brand name may go back as early as 1915. Meritas materials were surface-coated ones in a four-ply construction. (Lower cost, two-ply versions might have also been offered, but your author has no record of this.) Standard Fabrics certainly had the capability to make pyroxylin surface-coated fabrics, but may also have made counterpart top materials with a rubber outer coating. This brand seemed to enjoy its best success in the 1920s and much of the 1930s. The advent of the all-steel sedan roof in the mid- to late 1930s decimated a major part of the market for Meritas roof fabrics. Standard Fabrics likely offered suitable coated fabrics for other artificial leather applications.

MOHAIR

In the textile industry, this properly referred to yarn and cloth produced from mohair fiber - the hair of Angora goats. In automotive textiles mohair was a robust and very cleanable fabric, used both for top material and for closed-car seating fabrics (the latter was usually made up with a pile surface). The term was indiscriminately used and in the top material field it generally meant a rubber-combined cloth topping having a face fabric of mohair yarns and cotton yarns, or entirely of mohair yarns. It was introduced to the North American auto industry in 1907 by J.C. Haartz of Boston, MA. Other makers followed suit. The period of greatest use was from 1907 through 1915, although some usage occurred in the United Kingdom into the 1950’s. Some early advertisers claimed to offer “silk mohair” and “cotton mohair”. The former was untrue. The term “mohair” is still used in the United Kingdom to refer to rubber-combined cloth “hood” (top) fabrics, although we are not aware of any such material containing true mohair.

Mohair exterior cloth on period top materials can be distinguished by two senses. The mohair cloth feels harsher than comparable cotton cloth (such as on the top material lining). In appearance, fresh surfaces of mohair cloth are shinier than cotton (imparting a synthetic-looking sheen). Under magnification (use at least 10X magnification), mohair fibers and fiber-ends look like bundles of fine wires, quite distinct from cotton or wool fibers.

NAUGAHYDE®

Surface-coated fabric made for automotive soft trim and later for furniture by the U.S. Rubber Co., later Uniroyal. This trade name has seen active use since the 1920s. In their earlier years of business, some styles of Naugahyde were made for use as roofcover material on closed-body cars and on California tops.

NEVERLEEK

Surface-coated, 4 ply material made by the F.S. Carr Company in Massachusetts from 1912 through 1930. The brand was particularly popular in the late teens and in the twenties.

OIL CLOTH

True oilcloth (impregnated with a form of linseed oil or equivalent) was used for the top decks on commercial vehicle bodies and a few closed-bodied cars prior to 1940. It was also used for rain-curtain material on early open-bodied buses. Where used on vehicle-body top decks, where it was not subject to much folding or flexing, the oilcloth was sometimes painted to match the rest of the upper vehicle body, or in another color suitable for the roofing application (i.e. silvery color on trucks). So-called “oilcloth” on the market today is usually a lightweight vinyl-coated fabric with decorative prints for table covers and so forth, and is not suitable for vehicle roofing applications.

|

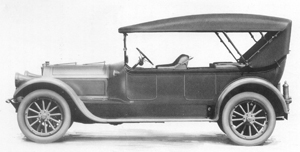

ONE-MAN TOP One of the drawbacks of extendible touring car tops used through around 1915 was the challenge of raising or lowering them. It normally took two people to do the job, although one strong and agile person might be able to do it. Top makers refined the top frame construction to make a structure that one person could truly manage. This arrangement also reduced the obstacles of bow supports along the sides of touring cars. One-man tops came onto the U.S.A. market around 1915 and supplanted the use of the older extension tops on touring cars. |

ORLON

In the textile field, this was DuPont’s trade name for acrylic fiber, tested for convertible topping use in the late forties. From about 1951 through 1956, several top material makers used Orlon cloth as the facing on some 3 ply cloth toppings. During most of this time, it was only offered in its “natural” color of cream white (which would yellow noticeably with prolonged weathering). After 1954, black Orlon became commercially feasible, but by 1957 only Mercury continued to offer Orlon tops, and that was the last year. The cloth was of very fine weave and is sometimes mistaken for vinyl.

PANTASOTE

A leading brand of top material synonymous with surface-coated topping in general. The Pantasote Company of New York offered several varieties of top materials by 1905 at which time they introduced the first surface-coated, 4 ply material. This latter offering had a unique surface coating that could withstand exposure to gasoline and oils. Thus, it became one of the favored choices of carmakers throughout North America. Pantasote offered the standard black surface coating (with at least a few choices of embossing patterns by the mid-teens) as well as brown and two shades of red. The latter three options apparently had limited use but set the brand apart in this regard. Pantasote seems to have been an exclusive producer of surface-coated, 4 ply material prior to 1912. Even with numerous competitors in this construction after 1912, Pantasote maintained a strong position in the top material field into the 1930s. The trade name was used generically for surface-coated, 4 ply toppings. The Pantasote Company performed their manufacturing work in Passaic, NJ, and also produced lighter-weight coated fabrics for other applications, notably window-shade material for railroad cars (they apparently were exclusive suppliers to the Pullman company), and in later years for decorative wall covering materials for the building construction trades.

PIECE-DYED

For single color (monochromatic) cloth, it was usually more practical to weave a cloth and dye it afterward. The “piece” of fabric would be dyed in a vat, or on a finishing line.

PONTOP

A DuPont coated fabric trade name. This one applied to a line of surface-coated top materials for open and convertible cars as well as for closed car top decking. The earlier Rayntite product line was apparently merged into this product line by the early 1920s.

POWER TOP

A self-raising, self-lowering top powered by some form of the electromechanical drive system. In the United States, the first commercial power top was offered by Plymouth in 1939. Within a couple of years, Cadillac and Packard had offered the feature. Power tops became very prevalent on traditional convertible cars in the American market from the 1950s onward.

PYROXYLIN

A coating substance used on automotive trim materials for many years up to the 1940s. It was a cellulose nitrate compound and was used on a wide variety of coated fabrics for automotive and many other uses. See Details of Components, Coating Compounds.

RAYNTITE

DuPont was most active in the top material market prior to 1930, this was the trade name for their surface-coated, 4 ply topping, first offered about 1915. By the early 1920s, this product line apparently merged with their top deck material line under the name Pontop.

RETRACTABLE HARDTOP

A bizarre aberration contrived by misguided stylists and electro-mechanical engineers looking for something to do. The idea was perpetrated in limited production in Europe by Peugeot in the mid-1930s. Ford took it into volume production with their Skyliner “convertible” in the mid-1950s. By about 2005, the concept was like a virus, popping up everywhere, but did not greatly supplant fabric soft-tops. The concept has subsequently gone quiet again, which suits us fine.

Please take this definition in jest, and not too much in fact. We make convertible-top material after all.

|

ROOF-COVER A styling feature for closed-bodied cars of many ages. The term tends to apply to the coated-fabric covers that reach to the side window tops or drip-rails, and down the back of a sedan or coupe top to the beltline of the car body. Also, see deck/decking. This kind of styling treatment was first popular with the California Tops in the years around 1920 and on closed-bodied cars of the 1920s and 1930s. The concept enjoyed moderate popularity in the late 1940s and early 1950s. The American auto industry went wild with the concept in the late 1960s and through the 1970s with the so-called vinyl landau top. Roof-cover styling persisted with the modern simulated convertible roof treatment through 2005, and on the tops of American stretch limousines. |

RUBBER-COMBINED

The cloth top material construction in which two layers of cloth are put together, or combined, using an intervening rubber film to yield a 3-ply fabric. See Figure 1 and text in the General Terms and Types section.

SHEETING WEAVE

Similar in nature to duck weave, yarns alternately go over, then under the intersecting yarns. Sheeting fabrics usually have finer yarns and a more open weave structure than duck weave cloth.

SINGLE TEXTURE

A two ply top material construction consisting of an exterior coating on cloth substrate (see Figure 2 and text in the General Terms and Types section).

SOLUTION DYED

Fiber, and its resultant cloth that is synthetic and produced from a colored plastic melt stock. The color is integral to the fiber, producing excellent colorfastness.

SONNENLAND®

This is the well-known “original German” cloth top material (also known by the name Happich) produced by Rode and Schwalenberg GmbH (now Haartz GmbH) since 1972. In about thirty years of making Sonnenland, product evolution resulted in several variations within this line, most of which remain available or in production. Sonnenland almost invariably consists of a mostly, or all-acrylic exterior cloth, rubber-combined with the well-known dobby-weave (criss-cross pattern) inner cloth.

|

SPANISH PRINT / SPANISHING In the leather and coated fabrics industries, these terms refer to a two-tone coloring to the visible surface of the material, and the techniques by which the effect is produced. In general, Spanish prints were used for pyroxylin-coated fabrics (artificial leathers) and true leathers for seat upholstery in open and convertible cars. Another generalization is that the two-tone effect was imparted by a relatively darker “ink” being spread into the creases and low spots of the material surface, although a lighter, contrasting “ink” was occasionally used. When so-called “California tops” were popular in the ~1918 through ~1925 period (at least in the U.S.A.), many had decorative roof covers of Spanish printed pyroxylin fabrics. Colors and grains varied and reflected the sometimes outlandish esthetic taste in the 1920s. DuPont’s Fabrikoid and U.S. Rubber Company’s Naugahyde were just a couple of the best-known brands of artificial leathers that included Spanish print materials in this time period. |

SPORT TOPPING

With the resurgent interest in cloth top materials in the 1920s, sport topping emerged, referring to the high-style cloth toppings then coming into use for the sportier convertible and open bodied cars. Haartz’s founder, J.C. Haartz, claimed to have originated this term, and no one ever disputed that. Sport topping became synonymous with convertible topping in general, both cloth and vinyl, through the 1950s. Some people continue to use this alternate term.

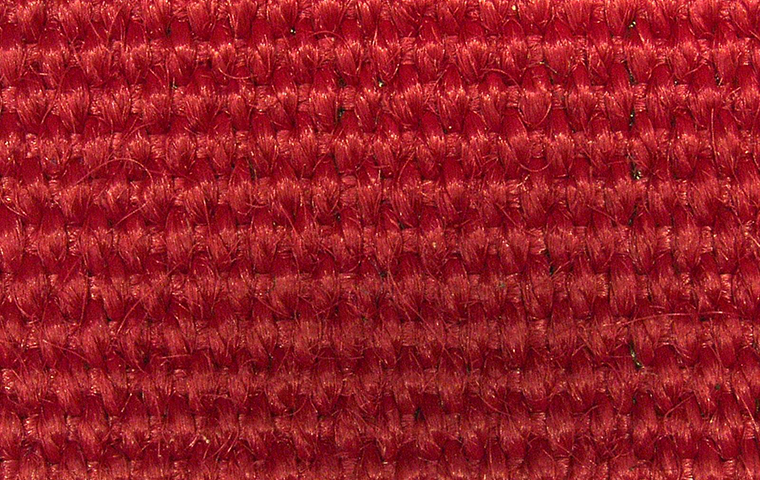

STAYFAST®

An acrylic-faced cloth top material produced by Haartz since the late 1970s. Because of the excellent colorfastness of the outer fabric, Stayfast became well accepted for new and replacement convertible tops, and in the antique car restoration field. Stayfast is an active registered trademark of Haartz.

|

TEAL In the late 1920s and through the 1930s, DuPont offered a line of rubber-combined cloth top materials under the Teal trade name. The occurrence of this trade name in automotive trim specifications will be evident if the word “teal” seems to contradict an adjacent color name (i.e. “weatherproof top of gray teal cloth”). |

TOP DESIGN

There is more to this topic than can be easily covered in this feature, but here are a few basic points about the field. As with other automobile technology through time, the field of folding top design has grown more sophisticated. European makers seemed to have put a bit more styling effort into top design than did North American makers, yet on each continent, the designers followed two schools of thought. Some preferred smooth exterior lines of a top, while others liked to accentuate the top bows, deliberately designing the top pattern to do this. The latter look came to be known as the “starved horse” or “starved cow” look. As soft tops aged and weathered, they could take on this look anyway. In the smooth-top school of design, some European makers would pad the top to help accomplish the appearance, but this practice was rare in North America. As car styling advanced through the 1930’s North American makers trended toward concealing the folded top in the lowered position, while European styling continued to embrace an external position for a folded top. Power-operated tops debuted about 1940. These trends continued into the 1950s. European makers later shifted toward concealment of the folded top. With advances toward more streamlined car body styling in the last five decades, the task of concealing the top has become more challenging, compounded by the trend to power tops that required less and less effort on the part of the car operator. Modern top design has to take into account the folding dynamics of the frame and top material, and the balance between reliable design and compact stowage. The well-known General Motors “scissors top” was a step in this direction. Modern “Z-fold” tops allow the forward part of the folded top to also replace the top boot of older designs.

|

TOP DRESSING Specialty paint or dye for renewing weathered soft tops. Back in the era when materials would fade before physically wearing out, top dressing was widely available for refreshing the surface of the material. The paint-like varieties were suitable for surface-coated top materials. Others were more like fabric dye, for use on canvas top materials, either on the exterior or interior surfaces. The example illustrated here was for use on black, surface-coated materials. Top dressings came onto the market as soon as the automobile industry began and continued among the common car care products into the 1950s. Most brands were formulated to be applied by brush. |

UMBRELLA TOPS

In the very early days of the U.S. auto industry, before it was common practice to outfit cars with tops, there was a minor market for accessory umbrella tops for use on two-seater car styles. These were not intended for protection in inclement weather, but for shade on sunny days. Despite efforts of makers to offer a solid design and good attachment to a car, umbrella tops were susceptible to wear and breakage from vibration, and the market for this accessory vanished by 1910.

VINYL

The common name for polyvinylchloride (PVC). Although a discovery from plastic polymer science of the 1920s, it took thirty years of advancement to develop a version robust enough for automotive exterior use. Flexible vinyl as used for automotive soft trim became popular for upholstery in the late 1940s. A convertible top material of vinyl first came onto the United States market in the early 1950s for replacement topping. Widespread acceptance by the domestic carmakers came in mid-decade.

WIRE-ON

A widely used category of top-bow welting. See Binding and Welting.

WELL LINING

Material used for lining the top well where a lowered and folded soft top retracts (in the convertible body styles that conceal the lowered top). Being a simple, protective envelope, the coated fabrics used for this purpose were lower-cost, plainer materials in general. This application of coated fabrics came into more widespread use in convertibles from the late 1940s and onward in North America. During the 1950s and maybe 1960s some used colored cloth to harmonize with soft top color. Later practice was to use a more standardized black material.

YARN DYED

Cloth woven from pre-dyed yarns, usually of multiple colors.

ZAPON

Artificial leather produced by a company of the same name in New Jersey from the mid-teens through the 1930s. They produced some surface-coated top materials. Zapon may be best known for the artificial leather they made for fabric-skinned car bodies of the 1920s, particularly those built by Weymann.

Copyright © 2004-2021 The Haartz Corporation. All rights reserved.

Sonnenland®, Stayfast® and Twillfast® are registered trademarks of The Haartz Corporation. All other trademarks and copyrights are the property of their respective owners.